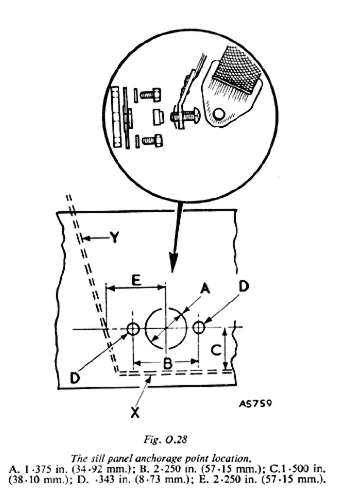

Sill

Cut a l-3/8 in. (34-92 mm.) diameter hole in the sill

panel forward of the heel board 'Y' and 1-1/2 in. (38-1 mm.) from the floor

'X' also cut two 11/32 in. (8-73 min.) as shown in the illustration.

Insert the sill tapping plate through the 1-3/8 in.

(34-92 mm.) diameter hole using the 7/16 in. (11-11 mm.) diameter screw to lift

the plate into position. Place a spring washer on a 5/16 in. (7-94 mm.) diameter

hexagon head screw and pass it through the cover plate with the register away

from the head of the screw and attach it to the sill and tapping plate. Remove

the 7/16 in. (11-11 mm.) diameter screw and finally secure the cover plate with

the second 5/16 in. (7-94 mm.) diameter hexagon head screw and spring washer.

Cut a 1 in. (25-4 mm.) diameter hole in the sillboard

trim as to clear the projection of the mounting bracket, and so coincide with

that of the hole drilled in sill panel.

Place the bracket and waved washer, the shouldered

distance piece (the smaller diameter of which will slot into the bracket) and

plain washer on the 7/16 in. (11-11 mm.) screw provided and screw the assembly

into the hole in the sill.